Fuses are an essential part of home, office, and shop electrical wiring systems. Used to protect the circuit from overloading or short-circuiting, fuses help prevent fires and possible hazardous situations. There are many different types of fuse designs available on the market today; each is designed for a specific level of protection as well as serving one or multiple needs all at once. In this blog post, we will explore what is a fuse, how it works, and the different types that you might see in your everyday life! Keep reading to find out more about these powerful little pieces of metal that keep us safe!

What is a Fuse?

A fuse is an electrical device that rapidly interrupts a circuit in case of a sudden surge in electric current, thereby protecting the wiring from damage. Fuses are generally made of metal and have two wires coming out of them: one connected to the circuit on one end, and another wire that connects to the external power source on the other. When there is an increase in the current above what it should be, the metal inside heats up and melts, breaking the circuit connection and stopping any further electrical flow.

Fuses prevent potential fire hazards caused by abnormal current levels, so they are essential components for household wiring and industrial applications. Fuse sizes vary depending on their purpose, and it’s important to select the correct fuse for a given application. If a fuse is too large, it may not blow quickly enough when a current spike occurs; if it is too small, then the device may short-circuit or overheat. Fuses also come in different types, such as fast-acting or slow-blow fuses. It’s important to know which type of fuse you need before purchasing one.

Fuses are often used in tandem with circuit breakers for added protection against overloading circuits or short-circuiting them. Both devices protect wiring from potential damage, but whereas fuses use a thermal element to open up a circuit when too much current flows through, circuit breakers have a mechanism that trips and stops currents above its rating. Most homes have both types installed to ensure optimal safety.

How does a fuse work?

A fuse is an electrical component designed to protect electrical circuits from overloads. It consists of a metal strip or wire that melts when too much current passes through it, thereby interrupting the flow of electricity and preventing damage to the circuit. The metal strip can be made of any material with a high melting point such as copper, aluminum, silver, or tin-lead alloy. For the fuse to work properly, it must be sized correctly for the circuit it’s protecting. If the fuse is too small it won’t be able to handle the required amount of current and will blow prematurely.

On the other hand, if the fuse is too large then there won’t be enough resistance and thus no protection against an overcurrent. When the fuse blows, it must be replaced with a new one that is rated for the same current level as the original. Over time, repeated overcurrents and tripping of the fuse can lead to corrosion and weakening of the metal strip, so regular replacement is recommended.

Fuses are an important safety feature in any electrical system, as they provide protection against dangerous electrical surges and prevent fires due to overloads. Fuses are typically found in most appliances, power strips, circuit breakers, and other outlets where electricity enters a building or residence. Always be sure to check your fuses regularly and replace them when needed to ensure the safe operation of your electrical systems.

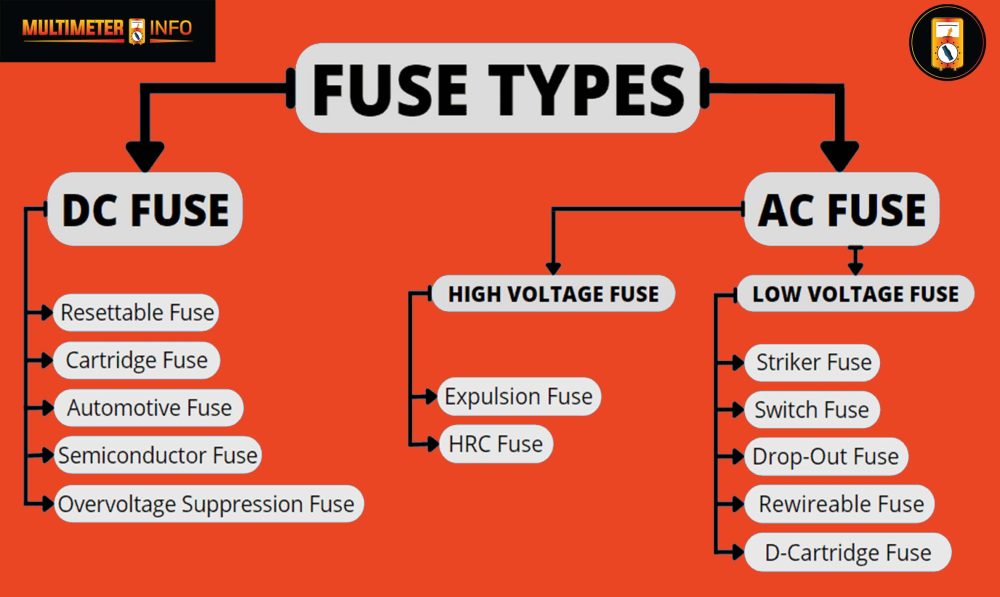

FUSE TYPES:

The types of electrical fuses are divided into categories based on working principles, construct, and applications.

DC Fuses:

A DC fuse is designed to protect electrical circuits and equipment from overloads caused by a short circuit of direct current. It works on the principle that the high current flow in a short circuit produces heat, which causes the fuse wire to melt and break the circuit.

AC Fuse:

An AC fuse is used for protecting electrical circuits and equipment from overloads caused by alternating currents. Its working principle involves sensing an excessive current that causes an electromagnet to attract a spring-loaded plunger which breaks or opens up the circuit via a contact arm.

Low Voltage Electrical Fuse:

This type of fuse operates at around 120 volts or less and protects against overcurrent conditions in low-voltage applications such as residential wiring systems. It is often used in homes and commercial buildings.

High Voltage Electrical Fuse:

This type of fuse operates at greater than 120 volts and is designed to protect high-voltage electrical circuits from overcurrent conditions. It works similarly to a low-voltage fuse but with higher temperature ratings and higher current ratings.

Cartridge Fuse:

A cartridge fuse consists of an enclosed cylindrical metal tube containing a metal wire that melts when excessive current passes through it. This type of fuse can be easily installed in applications such as power distribution systems, motor controls, or industrial installations.

D-Type Cartridge Fuse:

The D-type cartridge fuse features dual element construction with one element being the main fusing link while the other is a supplementary link. This feature provides additional protection against the risk of overload and short circuits.

Link-Type Cartridge Fuse:

The Link-Type cartridge fuse is designed with two fuse elements in parallel, to reduce the impedance of current flow and allow greater current carrying capacity. It is suitable for applications such as industrial motor protection, battery charging, and power supply systems.

Rewireable Fuse:

Also known as an HRC (High Rupturing Capacity) fuse, this type of fuse features a durable ceramic tube that can be reused after replacing the damaged element inside it. Its design makes it suitable for use in extra-high-voltage applications where replacement fuses are not available.

Striker Fuse:

This type of fuse operates similarly to a low-voltage electrical fuse, but with the addition of a striker plate that is designed to sense an overcurrent condition and trip the circuit. It can be used in applications such as motors, transformers, and power distribution systems.

Switch Fuse:

A switch fuse is designed with two elements; one is the main fusing link while the other acts like an on/off switch. This feature makes it suitable for use in motor control circuits as it allows manual resetting of the circuit after overload trips.

Expulsion Fuse:

This type of fuse employs a high-pressure gas system instead of wires or elements to protect against over-current conditions. When excessive current passes through, this pressure system is activated and causes the fuse element to be forcibly ejected.

Drop-out Fuse:

A drop-out fuse operates by sensing an overload condition and causing the entire element to melt, thereby opening up the circuit and preventing further damage due to excessive current flow. It is suitable for use in industrial applications or other high-voltage systems.

Thermal Fuse:

This type of fuse employs a temperature-sensitive device that senses heat generated from excessive current flow and breaks or opens up the circuit when it reaches a predetermined level. It is used in many household appliances such as hair dryers, microwaves, coffee makers, etc.

Resettable Fuse:

Also known as a polyfuse, this type of fuse is designed to reset after overload trips, thereby allowing the circuit to be used again without having to replace the fuse. It is often seen in consumer electronics such as cell phones, laptops, and other digital devices.

Semiconductor Fuse:

This type of fuse employs a semiconductor material instead of wires or elements to protect against overcurrent conditions. When excessive current passes through, this material quickly melts and opens up the circuit. It can be used in applications such as power supply systems and motor protection circuits.

Voltage Suppression Fuse:

This type of fuse is designed with an internal pressure relief system that helps protect against both overvoltage and overcurrent conditions by limiting the amount of voltage or current entering the circuit. It is often used in sensitive electronic equipment such as computers and televisions.

Surface Mount Device Fuse:

This type of fuse is designed for use with surface mount devices (SMDs) and consists of a small, self-resetting element that prevents excessive current from flowing through the circuit. Its low profile design makes it suitable for use in tight spaces or confined areas.

Overall, there is a wide variety of fuse types available for different applications and industries. Depending on their design, some fuses are more suitable for certain applications than others. It is important to choose the right type of fuse for the specific application to ensure optimal performance and safety. By understanding the different types of fuses and their features, users can make an informed decision when selecting one that meets their requirements. With proper selection and installation, these devices can help protect electrical systems against dangerous overloads or short circuits and ensure safe operation.

Read more: Test Fuel Rail Pressure Sensor

How the fuse current rating size is calculated?

The fuse current rating size is calculated using a simple formula. The power and voltage values for the motor are divided, then multiplied by 1.5 to determine the recommended fuse rating size. For example, if the power of the motor is 500 watts (W) and the voltage is 20 volts (V), then the fuse rating size would be calculated as follows: (500 ÷ 20) x 1.5 = 37.5 A. This value should be used when selecting a suitable fuse.

It’s important to note that this formula only applies to AC motors; follow manufacturer guidelines if you are calculating fuse ratings for DC motors or other equipment. To ensure safety, it’s always best to err on the side of caution and select a fuse rating size higher than the calculated value. This ensures that the circuit is properly protected against overloads.

When it comes to selecting a suitable fuse, always consult with an experienced electrician or another professional who knows the specific application in question. Doing so will help ensure that you select a suitable fuse and that your electrical system is installed correctly for optimal performance and safety.

Fuse ratings are essential components of any electrical setup. Understanding how to calculate them helps to save time, as well as ensure optimum safety for all users of the system. Following manufacturer guidelines and consulting with professionals can also help make sure everything is done properly from the start.

Read more: Test Car Fuses With A Multimeter

Frequently Asked Questions:

It’s important to ensure that you choose the right type of fuse for your application based on its current rating and amperage needs. If you’re unsure what kind of fuse would be best for your application, consult an experienced electrician or contact the manufacturer of your device.

Yes, it’s important to always use caution when handling and replacing fuses. Make sure that you are wearing proper eye protection, as sparks can fly when a fuse is being replaced. Additionally, be sure to disconnect all power sources before beginning work on a fuse-related project. Following these simple steps will help ensure the safety and integrity of your electronics and appliances.

Using a fuse with the wrong amperage rating can result in serious damage to your electronics, as well as potentially being a fire hazard. It’s always best to use the exact amperage and type of fuse for any given application to ensure optimal performance and safety.

No, some types of fuses are not compatible with certain applications or devices and must be replaced with the correct type for them to work safely and properly. Always check what kind of fuse is needed before attempting to replace one, as using an incompatible type may lead to damage or potential safety hazards.

Conclusion:

In conclusion, fuses serve as safety devices in electrical circuits and are a critical part of the electrical system. By understanding the types of fuses available and their ratings, you can effectively use them to protect your circuits and equipment from overloading or short-circuiting. Remember to always follow safety procedures when working with electricity and consult a professional if in doubt.